Any good engineer likes it when life throws the conditions their way for a great experiment, and life has just thrown me several all at once. I have a six-year-old son, a two-year-old son, a six-month-old daughter, and until recently, a two-parent household. I’m not used to being a single dad of three, but my wife had an out of town family emergency that results in her being away for an extended period of this summer. I’ve decided that in order to survive the summer, I might have to re-engineer some of our domestic chore workflows, starting with how I approach laundry.

If necessity is the mother of invention, having the mother indefinitely out of town may be the father of invention. I’m free to try things that under normal circumstances might invoke an eye-roll, sigh, or out-right veto from my otherwise patient wife.

So I’ve been paying attention to little inefficiencies in my daily life while trying to keep up with tasks that my wife usually leads. Then I apply standard principles of industrial engineering and process optimization. When I find a process I can improve upon, I ask myself two simple questions:

- How much return on investment can I get from improving this process? Saving myself a few minutes might not be worth the time spent. Cost / benefit analysis cannot be overlooked when you are working with limited resources.

- How much trouble will I get in with my wife if she find out? Risk-hazard analyses are a critical part of changing any process or system.

The laundry time-suck problem

My first line of attack was laundry. For many years now, I’ve been aware that “doing the laundry” was not really the time suck that gives laundry a bad name. It’s actually “putting away the laundry” that seems to consume the most time. This has not always been true. Throughout the last several hundred years, much attention has been spent improving the processes and equipment for actually washing the clothes – always promising to save the user time. http://en.wikipedia.org/wiki/Washing_machine#Early_machines

As an engineer, however, I must take technology and prior advances for granted, and push onward. To date, few advancements have been made in “putting away the laundry”, other than perhaps the laundry basket and clothes hangers.

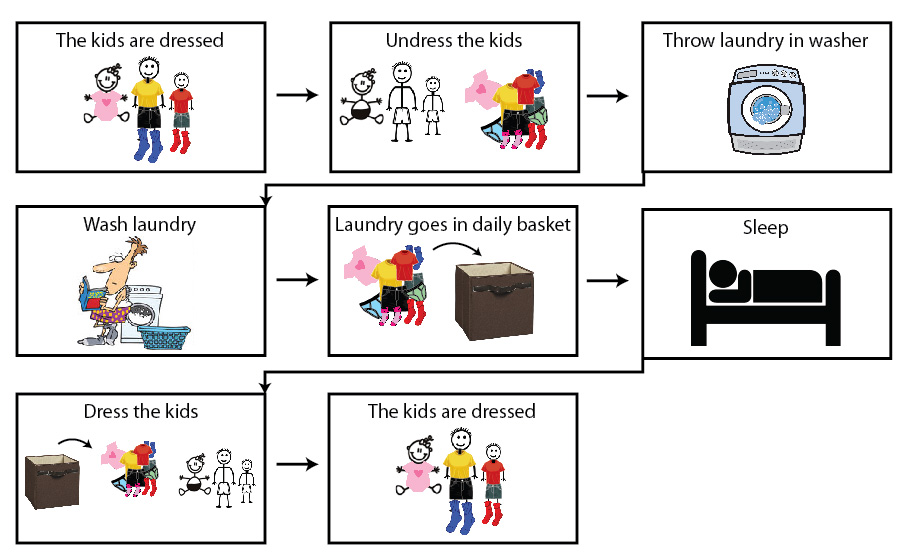

The crux of the problem is this – I spend an inordinate amount of time folding laundry downstairs (that’s where the TV is), loading it by categories into laundry baskets, trucking it upstairs to kids rooms, and then sorting it into drawers, cubbies, and hangers. There’s unique locations for socks, underwear, shirts, pants, pajamas, towels – all multiplied by three kids. I’ve illustrated the workflow in a process flow diagram, so we can see where the bottlenecks occur. I’ve highlighted the boxes that consume the most labor time.

The whole system presupposes that my kids need to peruse the closet with the luxury to choose which shirt they want to wear that day. That is absolutely not how my mornings go. While they are eating breakfast, I’m upstairs unsorting the clothes into a pile under my arm to truck back downstairs for assembly line dressing.

I have a clothes storage system that dictates unnecessary sorting stages that take hours. I realize this is a bold statement, but:

I’m declaring the kid’s closets and dressers are essentially obsolete until my wife gets back.

The Solution

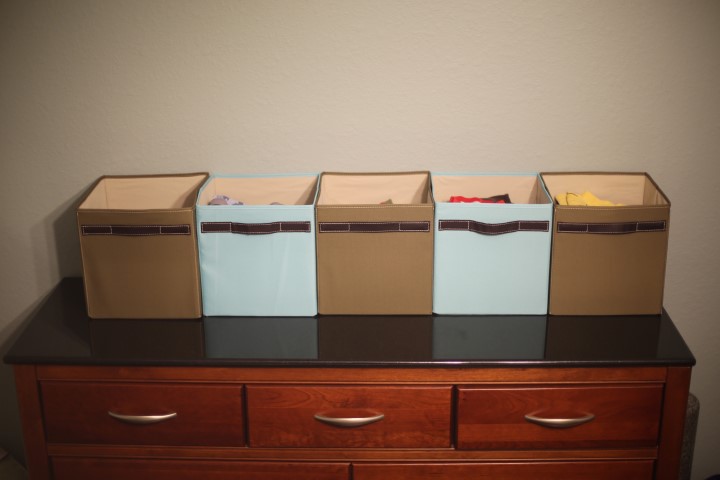

Here’s my new system: I have aesthetically pleasing baskets for each school day on top of my wife’s dresser. (irony unintended) Each basket gets clothes, bibs, pajamas, etc. for each kid to last the whole day. They go straight from the washer and dryer into the baskets. Every time we take off clothes, they go straight into the washer. Each night, after kid bedtimes, I run the washer. By the time I go to bed a few hours later, I have replenished another fluffy basket good for another day of surviving until my wife comes home.

As you can see from the new (probably temporary) process flow, I have eliminated the major labor stages almost completely. Despite what the diagram implies, I rotate among five baskets so that the kids teachers don’t question them wearing the same outfit every day. Otherwise I could totally optimize our clothing costs…

Often times when you set out to solve one problem, there are additional benefits from process improvements that may not have been foreseen originally. Here’s a few that I’ve noticed:

- For the first time in my life that i can recall, laundry is actually a task that can be finished. Every night when I go to bed, 99%* of the clothes in the house are clean and put away (*pajama exception).

- I am not nearly as likely to mix up socks with the wrong kid.

- My R2-D2 t-shirt is almost always clean.

http://www.target.com/p/closetmaid-premium-fabric-bin/-/A-14488570#?lnk=sc_qi_detailbutton

2 Responses

Now you have one problem that you might not have calculated. Marianne likes the new system and the feature she kikes the best is your doing the laundry.

Hum it may consume a lot of power & water don’t you think ?