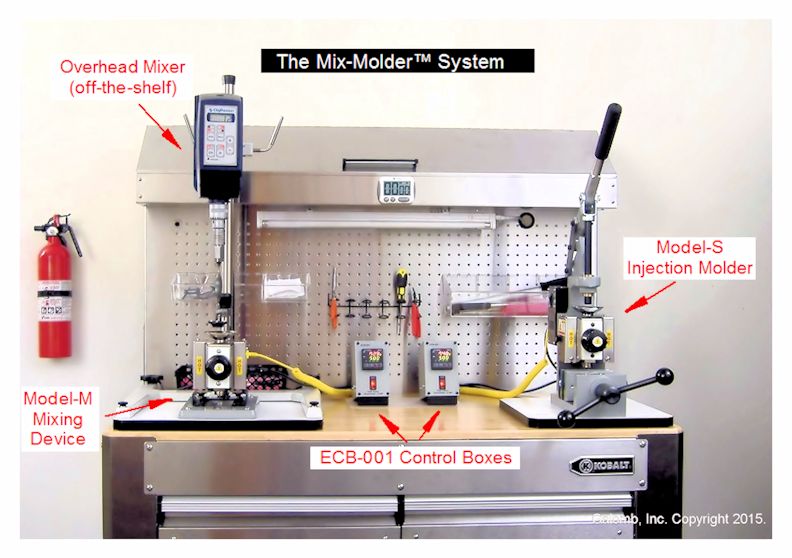

Sparx Engineering acquired the Mix-Molder(TM) system to evaluate polymer blends and determine optimum pigment loadings. Having previously worked with expensive capital equipment such as the Process 11, we were particularly interested in the effectiveness of the mixing system for blending additives. Experience driven effects observed from shear upon additives in reactive extrusion, presented a true evaluation of the Mix-Molder(TM) system to answer the fundamental question: For modification of engineering grade resins with additives, would the Mix-Molder(TM) provide sufficient mixing and shear to prepare representative samples for optimization of new products?

Several experiments presented the system with specific challenges. First, an alloy polymer blend of polycarbonate and polyester was impregnated with black pigment. Application of the Mix-Molder(TM) system generated samples that were indistinguishable from native resin, as measured by TGA (thermogravimetric analysis) and DSC (differential scanning calorimetry). When the same process was repeated using the injection molder without mixing, the sample showed significant deviations from the TGA/DSC. Given this was performed with an alloy blend, the data indicates in the absence of mixing the two polymer systems phase-separated, and the pigment was clearly not distributed uniformly.

In a different experiment, a pigment was blended with a secondary polymer system to lower the melting point. In the absence of stirring, semi-crystalline regions were apparent in the clear polymer, whereas when the mixing system was employed, the blend produced a clear resin. It can be concluded the Mix-Molder(TM) was able to handle the resin blends and produce a sample that differed greatly when not mixed.

Finally, in a separate experiment, these blends were subjected to ultrasonic welding. It was determined, using water, that mixed samples were water tight after welding, whereas samples without mixing leaked water. With the importance of homogenous samples for ultrasonic welding, it is apparent the Mix-Molder(TM) provided sufficient shear to produce samples that met the specifications of the product. In the absence of the mixing system, samples produced only with injection molding showed a decrease physical performance, both quantitatively with TGA/DSC and qualitatively with the results from ultrasonic welding and visible semi-crystalline regions.

Conclusions:

The Mix-Molder(TM) system provides excellent performance for mimicking capital equipment for the prototyping of engineering grade resins with additives. With its very affordable price tag, the Mix-Molder(TM) can accelerate results and answer fundamental science question about resin quality for commercial prototypes. This provides the ability to generate the data to support investment, acquisition of capital equipment, filing a patent or engagement with fee-for-service polymer conversion specialists. The power of this system exceeds expectations for performance with engineering grade resins.