Our engineers can rapidly come up to speed on existing designs in order to fix problems, make modifications, or reverse engineer designs.

Rapid Prototyping

Sparx can quickly get to a “Works Like” prototype by rapid iteration and “fail-fast” methods.

- Access to a variety of additive manufacturing systems through both in house equipment and external vendors

- In house fabrication tools for quick CNC machining, 3D FDM, 3D powder and 3D SLA printer builds

- Multiple options for system controls

Advanced Simulation Analysis

- Structural and Vibration Analysis for Aerospace

- Modal, shock, static Analysis

- Finite Element Analysis for wide ranges of materials, component types and fully integrated assemblies

- Computational Fluid Dynamics (CFD) for flow analysis

- Multiphysics simulation

- Can analyze existing designs for weak points

- Analysis of complex linear, nonlinear, and weld analysis systems

Advanced Computer Aided Design (CAD)

Sparx has expert knowledge of all types of CAD software.

- Engineering drawings for manufacturing, assembly and patent documentation

- Complex assembly design

- Single part to complex assembly tolerance studies

- Photo-realistic rendering software

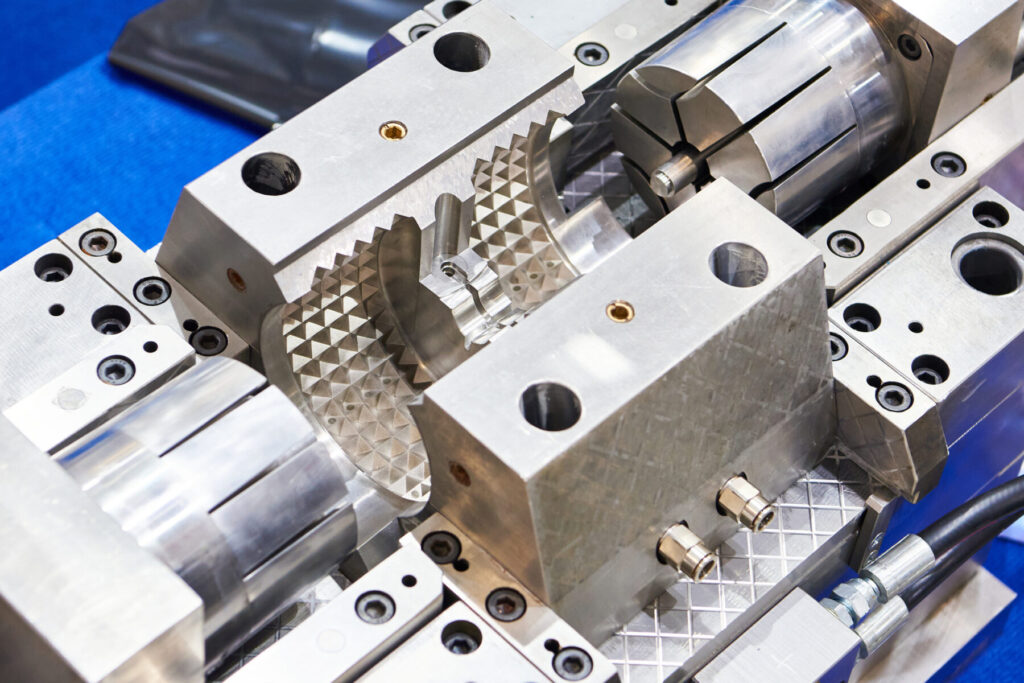

Injection Molded Part Design

- Experience with a variety of mold layouts to reduce cost

- Mold Flow simulation analysis

- Expert materials selection per application

- Custom material design

- Integrated features to minimize assembly costs

- Custom component design for high volume production using injection molding

- Large network of quick turn manufacturers

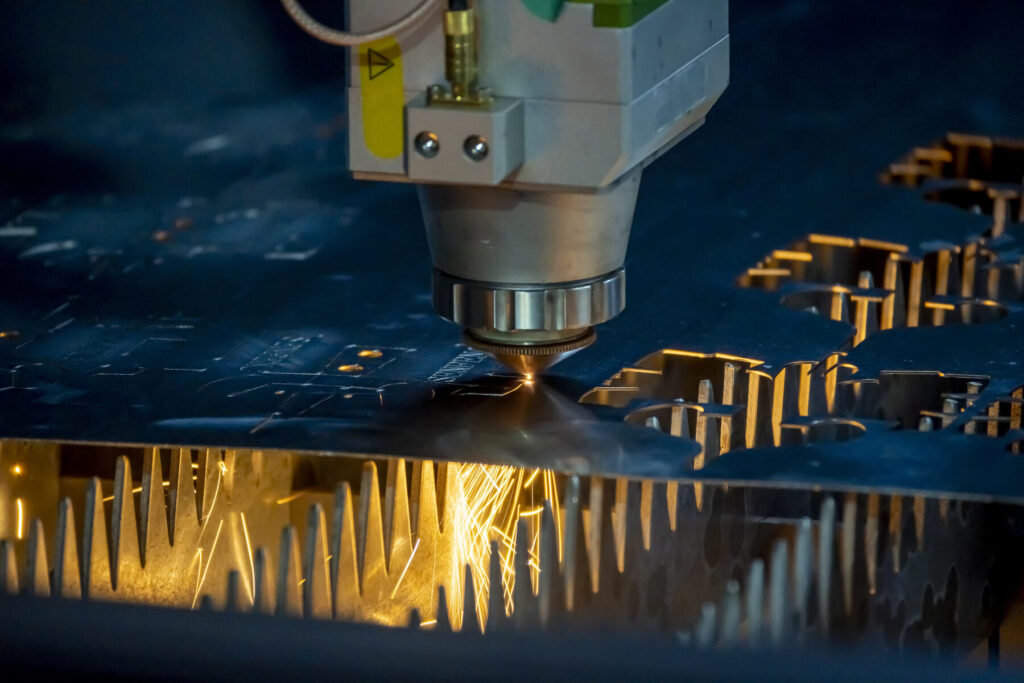

CNC and Sheet Metal Part Design

Sparx can design an optimized part for any major manufacturing process.

- Multi-axis CNC milling/turning component design

- Cost effective and detail oriented approach to manufacturing design for maximum precision and efficiency

Contact Us

With a focus and adherence to design for manufacturability (DFM), design for test, and a highly parallel workflow, Sparx is capable of quickly moving a project from conceptual sketch to production.